0

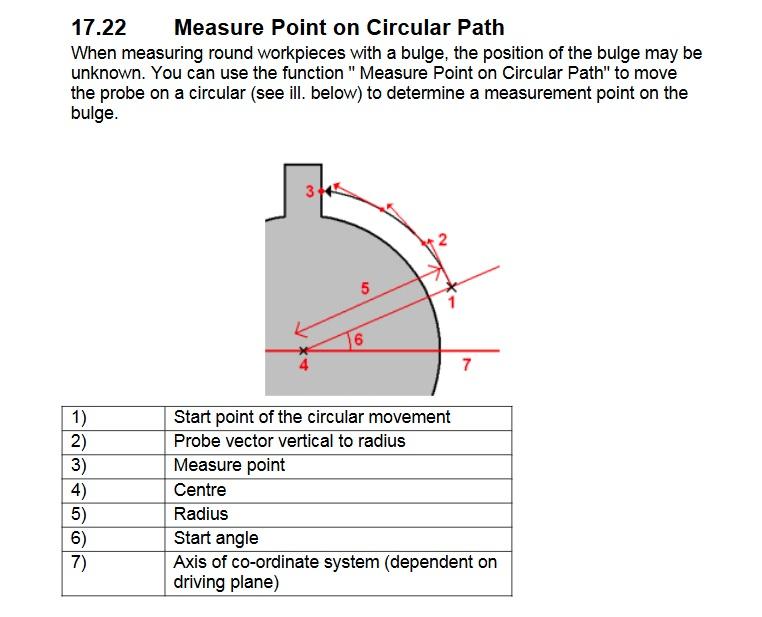

Measure point on circular path

M-Cosmos/Geopak (Mitutoyo) can measure a point on a circular path. This is useful in certain situations when rough aligning a round part or when the rotation of a radial feature is not necessarily clocked to other features on the part.

See this forum post for more details/examples...

PC-DMIS forum "How to search for point radially or using circular moves"

Here is the example from M-Cosmos/Geopak help file...

خدمة دعم العملاء من خلال UserEcho

Have you tried this? If you need a specific angle you can rotate your "current_alignment" to that clocking.

Hm, I'm not sure if that applies. What I'm trying to do is find that protruding feature in the first place. Imagine it's quite shallow, or on the ID instead of the OD. I want the machine to move in a circular path following the curve of the part until it contacts the surface that sticks out. Check the link to forum for other examples.

So your attempting to catch one or two of the corners? whats the measurement your attempting to capture?

That example picture is from the M-Cosmos/Geopak help, so it's not a real part.

This is the top face of the part I'm specifically working with. It's closed on the bottom, and those radiused notches are the only features on the part that are not cylindrical/round. I would love to be able to rough locate center of part from OD, then move to the middle of the notch and, following the ID curve, hit somewhere on the smaller radius corner. I could then do the same going other direction for a midpoint. It's not for a measurement, so it doesn't matter about probe comp being inaccurate. As long as operator can plop it down roughly square to machine I'm good. Right now, I have to have them lock X or Y axis and try to line up two corners as accurately as reasonably possible to the other machine axis. Very tedious.

Is the fixturing tight toleranced enough that you can have the CMM go to a radial position in x or y and and bang out 2 points perpendicular to the respect axis to create your mid point? or can you make small enough circles in those radii that regardless of clocking you'll always at least hit the radius, then intersect those corner radii with the ID? Then you'd get your 2 points to create the mid point. Sorry hard to draw with mouse LOL

Part is being placed on machine by hand, no fixturing besides two pegs to slide it against. Then operator visually aligns corners with machine axis best as possible. I do align using the radii with shorter arc before measuring them, but it's just a tedious and potentially problematic process that would be made extremely simple by being able to measure on a circular move like I'm describing.

This is dcc or manual? If manual I might would exchange that portion to doing a quick alignment and let the dcc mode do the radii part. So long as you get the manual fairly close the dcc will have better opportunity to do it correctly and in less time. Also are you scanning or 3 points?

Yeah, sorry, the radii are rough measured with DCC. Only manual part is the visual lining up to machine axis.

I don't have scanning probe, but I am taking a few more than 3 points both for aligning and measuring.

ahh bummer. Yeah that's a tough one.